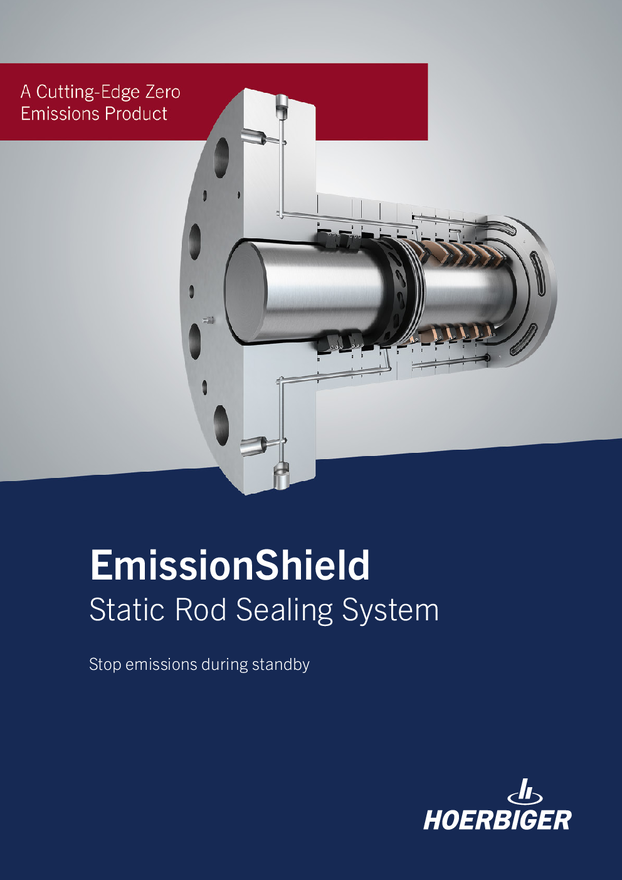

EmissionShield – Static Rod Sealing System

Stop emissions during standby

Effectively eliminate vented emissions

Conventional rod seals and packing cases are designed to seal gas inside the compressor during operation, but during standby conventional packing will allow pressurized gas to leak out of the compressor. Gas contained in the cylinders, volume bottles, heat exchanges, piping and other auxiliary devices is either blown down or is slowly depressurized to the atmosphere. In many cases this gas is vented directly to the atmosphere rather than burned via flaring. This is both a loss of potential revenue and a serious environmental problem. With EmissionShield, these vented emissions are effectively eliminated.

Self-activation makes it easy

Because the EmissionShield is self-activated and does not require an external control panel or pressurized gas to activate, it is substantially easier to operate, and eliminates the need for expensive and difficult-to-use conventional shutdown seals.

Reliable and easy to use for your emissions reduction goals

Our static rod sealing system is much more robust and reliable than conventional shutdown seals, because it does not have moving parts. It is not susceptible to dirt in the packing. It does not break and damage the other packing rings or the piston rod, even if used incorrectly. It can be used with any compressor, but is most beneficial for compressors that are intermittently in service or kept on pressurized standby. In combination with our ECP (Emissions Control Panel), EmissionShield is the key to enable net-zero operations in compression.

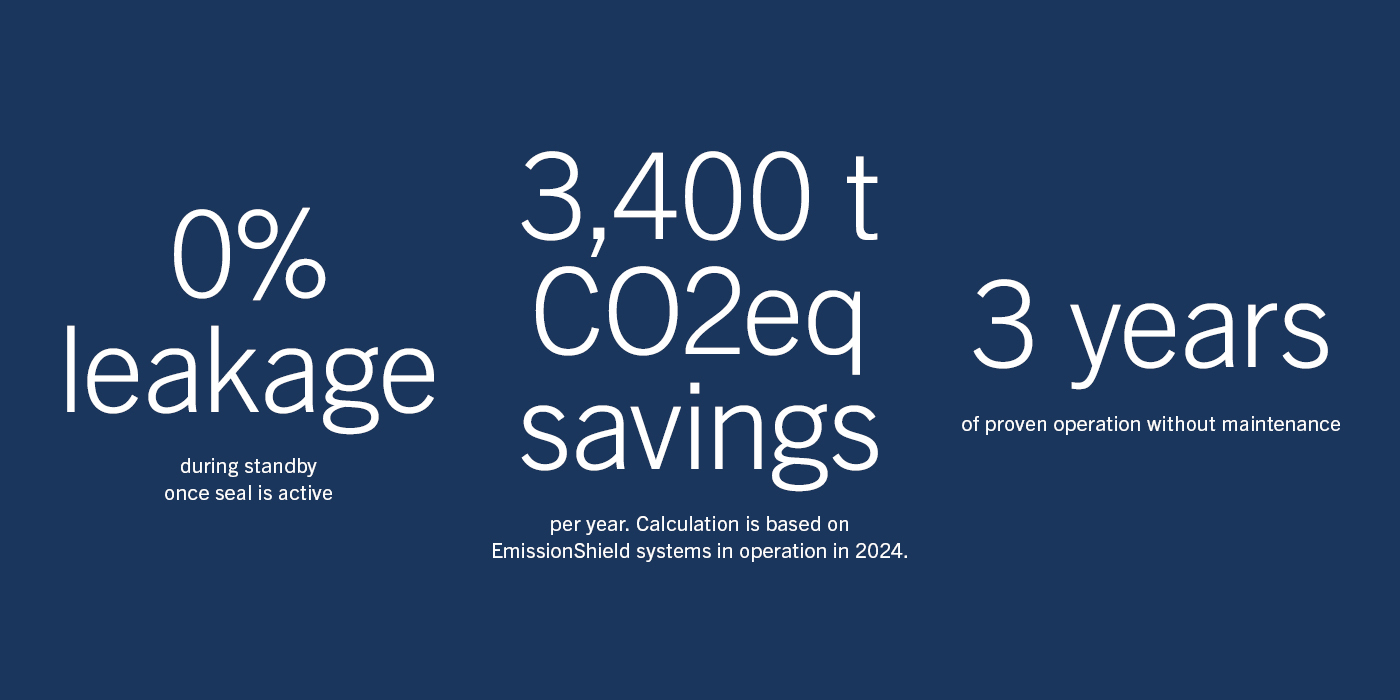

Using EmissionShield, we were able to measure a

97% reduction in our compressor’s vented emissions.

In terms of the compressor’s total CO2 equivalent

footprint, this corresponds to a 25% reduction.

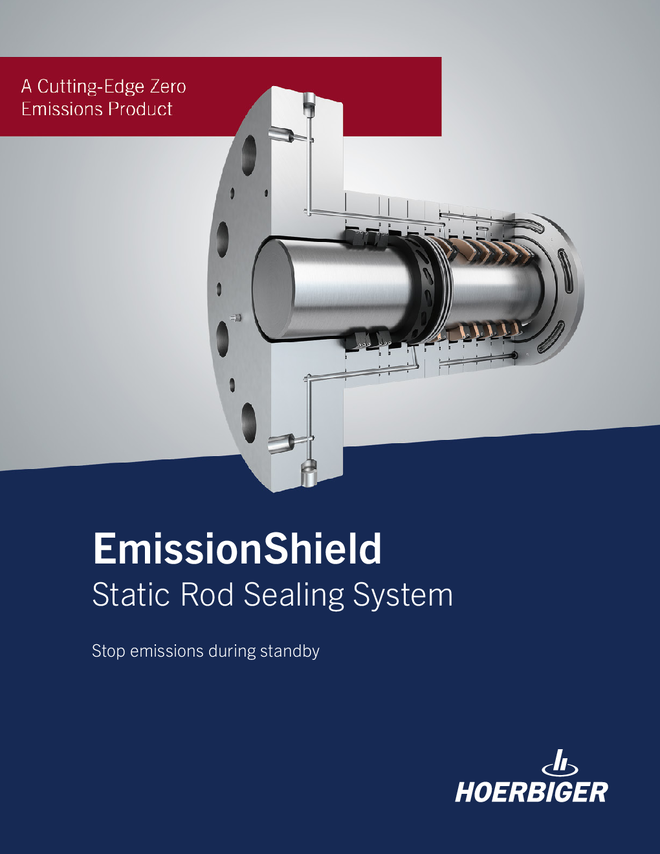

How does EmissionShield work?

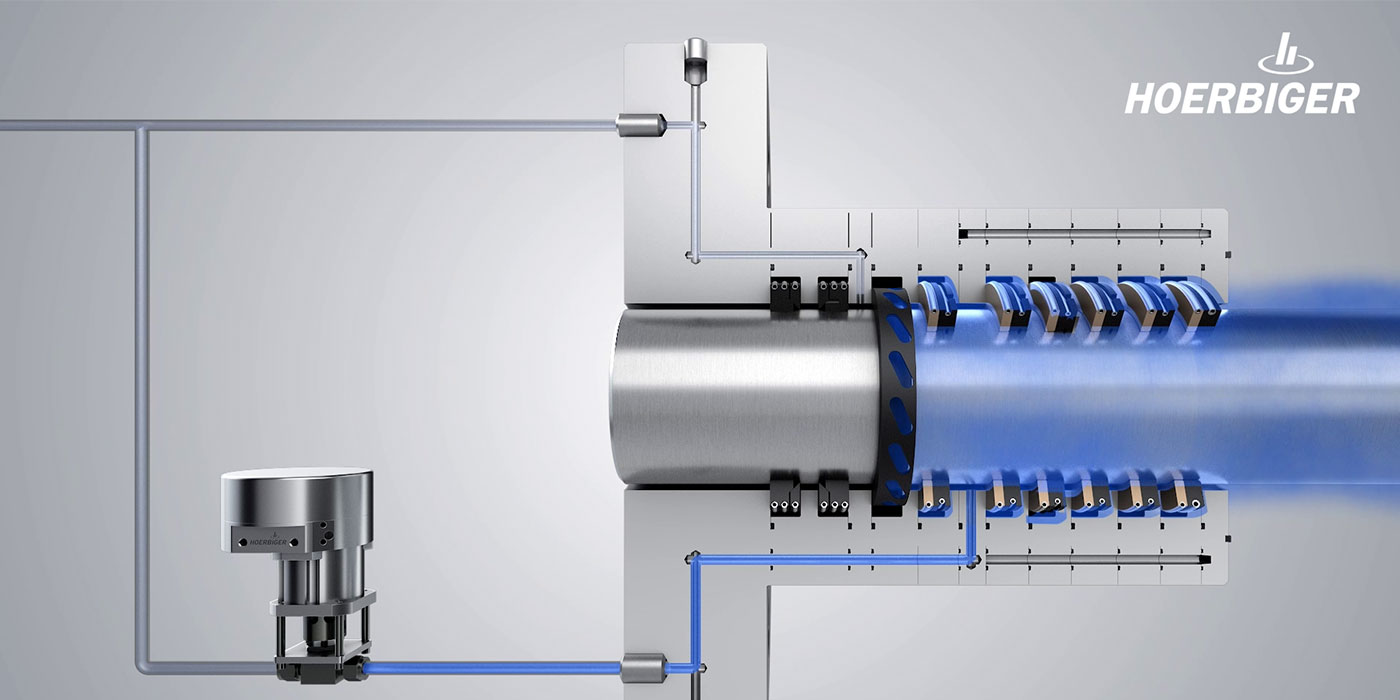

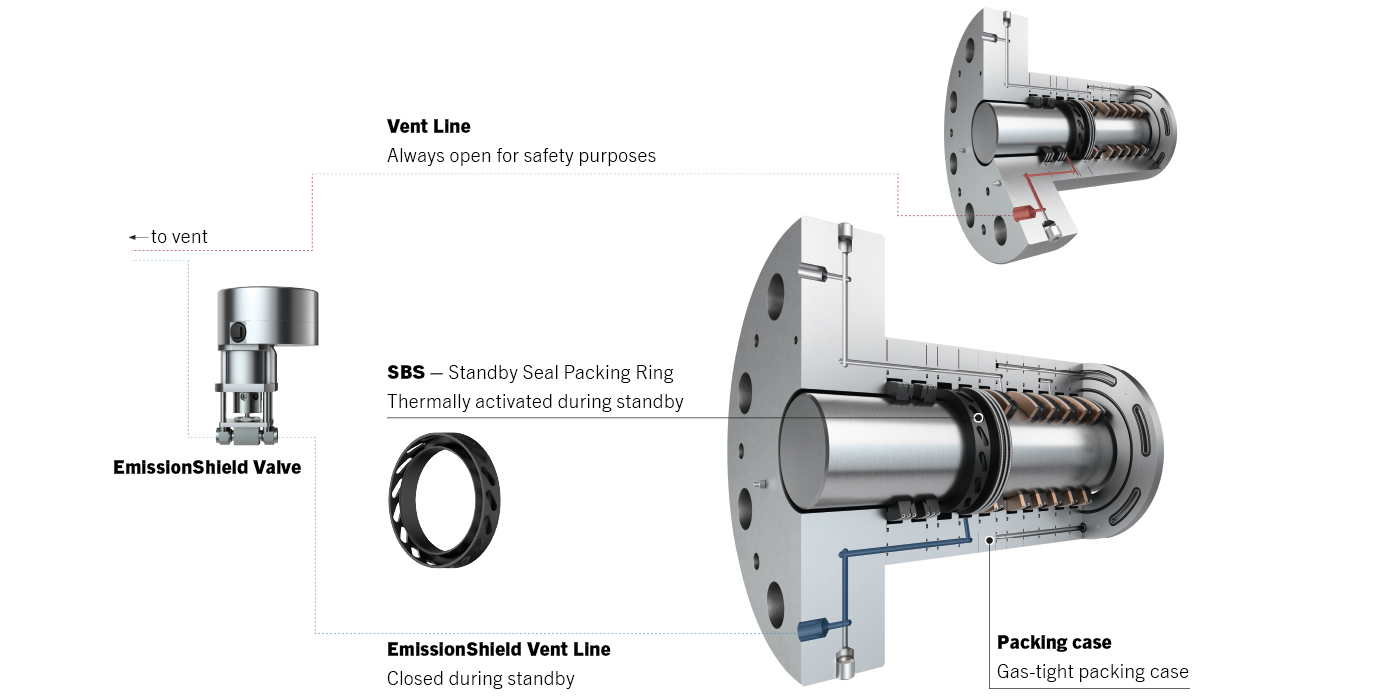

The EmissionShield packing is mounted on the rod, and is immediately gas-tight following installation.

When the compressor starts, friction causes the piston rod and packing case to heat up. This temperature increase causes the Standby Seal Packing Ring (SBS) to react and expand off of the rod.

While the compressor is running, the EmissionShield Valve is open to allow the EmissionShield Vent Line to control the gas which escapes through the packing rings/case. The traditional vent line in the packing case remains open at all times, guaranteeing the safe evacuation of gas from the packing case in case of any faulty activation of the valve.

When the compressor stops, the EmissionShield Valve closes. Within a few minutes, the piston rod begins to cool, and the Standby Seal Packing Ring contracts, creating a tight seal against the rod. At this time, the EmissionShield packing system is activated, preventing vented and fugitive emissions.

Seconds before the compressor restarts, the EmissionShield Valve opens, relieving the Standby Seal Packing Ring from cylinder pressure and allowing it to deactivate within a few minutes from restart.

Your benefits at a glance

| Feature | Advantage | Benefit |

|---|---|---|

| Gas-tight packing case design | Eliminates cup-to-cup leakage, allowing the compressor cylinders to remain pressurized indefinitely | Reduces emissions as the compressor can be utilized intermittently or kept on hot standby when needed with virtually zero gas loss |

| Single piece static seal ring | No mechanical components or moving parts inside the packing case or in contact with rod | Increases compressor reliability as the SBS Ring is not impacted by debris and does not wear out while the compressor is running |

| Thermally activated static seal ring | Does not require alternate activation medium (gas/ hydraulic) or costly control panel | Reduces installation cost and time through simple plug and play design |

Motorized EmissionShield Valve with spring-loaded mechanism and feedback signal | Available for 24 VDC or 110-240 VAC supply | Increases safety as the fail-safe valve design will vent the compressor in case of electrical failure |

| Class 1 Div.2 and ATEX Zone 2 certified | Ideal for all compressor types – rugged design is optimized for different environments | |

| Feedback signal can be used for system monitoring and diagnostics | Improves compressor reliability as the DCS will signal malfunctions before they can damage the equipment |

Brochure A4 Format

Letter Format

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.